Did you know that the shea tree's dead or green wood is utilized for building, fuel, and charcoal production?

Outside of the winter season, the modest charcoal trade provides a source of income for the locals. Walnut shells and oilcakes are also utilized as fuel.

Quality

In order to assure the quality of its product, Mali Shi has established a committed approach within its production process.

Quality

Buyers are increasingly asking for high-quality shea butter, however, with the current manufacturing environment in Mali not allowing for sufficient quality control, the commercial development is limited.

Mali Shi is involved in the supply of almonds upstream. Its primary goal is to assist shea collectors and producers in acquiring measurement and control equipment, enhancing the quality, process, and logistics of operations in order to satisfy export standards and compete in markets.

Downstream, special attention is devoted to the almond transformation process, which allows for management of the manufacturing stability.

Mali Shi has obtained a control tool that meets international requirements thanks to the technical assistance of its partner IFC.

-

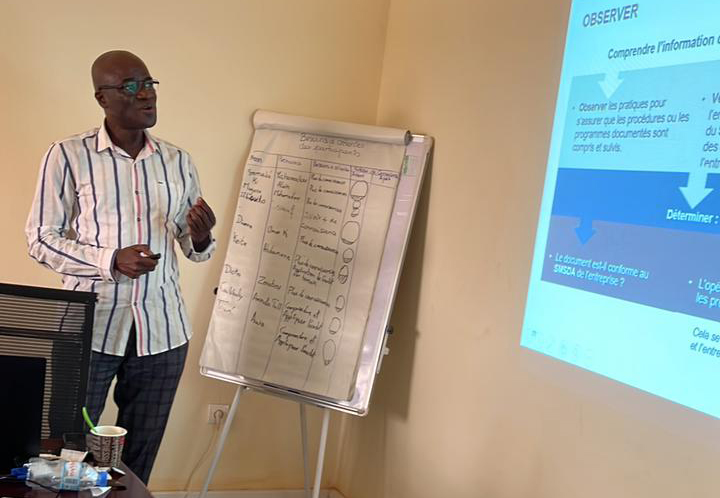

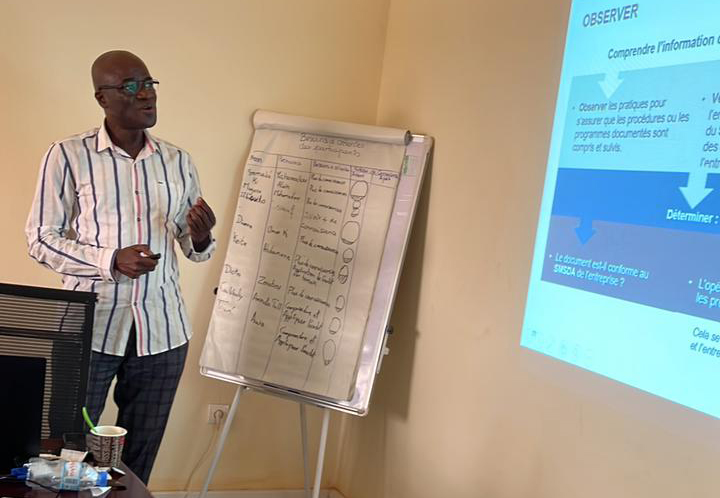

A complete SMSDA team (food, safety, and management system) has been established inside Mali Shi's organizational structure to increase quality control capacities.

-

Analyses are performed all along the manufacturing chain in an internal laboratory that opens 24 hours a day. Control analyses are performed from the time the almond purchases are sampled until the extracted butter is delivered.

All laboratory analyses are carried out in accordance with ISO standards

Acidity: ISO 660- 2020

Oil Impurities: ISO 663 - 2017

Humidity: ISO 665- 2020 Et ISO 662-2016

Fatty Matter: ISO 659 – 2009

In addition to these efforts, the quality department conducts ongoing training for all personnel of the plant in the following:

-

Workplace hygiene

-

Food security

-

Workplace safety

Technical assistance from the IFC is also provided in the formulation and execution of the HACCP plan (Hasard Analysis Critical Control Point).

In addition to these efforts, the quality department conducts ongoing training for all personnel of the plant in the following:

-

Workplace hygiene

-

Food security

-

Workplace safety

Technical assistance from the IFC is also provided in the formulation and execution of the HACCP plan (Hasard Analysis Critical Control Point).

As part of this process, Mali Shi had its factory evaluated by an agri-food expert consultant in order to identify strengths and areas for improvement. Following this assessment, concrete actions were implemented to meet the requirements of the ISO/TS 22002-1:2009 standard.

This commitment enabled Mali Shi to obtain its certification in 2023, successfully renewed in 2024 and 2025.

SMSDA Team

SMSDA Manager

Aminata B. Tall

Weighbridge Operator

Zeinab Dicko

Quality Controler

Awa toure

Shift supervisor - Production

Mahamadou Samake

Production Manager

Attaher AG Ahiyoya

shift supervisor - Production

Bakary Niambele

Shift Supervisor - Production

Oumar K. Diarra

Maintenance Manager

Mahamadou Magassa

Head of The Press Department

Issouf Ilboudou

Head of The Extractor Department

Alain Romanric KI

Zone Supervisor

Moussa Doumbia

Material Accountant

Dianka Demba